YTS Blog

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which

Conductive Polypropylene Air Diaphragm Pumps

Conductive Polypropylene Air Diaphragm Pumps are cost effective alternative to PVDF pumps in many applications requiring ATEX certification, high chemical resistance, resistance to ultraviolet radiation

Air Diaphragm Pump Start-up Pressure

As a rule of thumb, the start-up pressure of Air Operated Diaphragm Pumps should be set at 2,0 bar. Then, manually using air valve increases

Fluid Viscosity

For proper Diaphragm Pump selection understanding of fluids properties is mandatory. Fluid flow is highly dependent on the viscosity of fluids. Basically, viscosity is a

Pump Cavitation (suction cavitation)

Cavitation is a common problem in pumps, including Air Operated Diaphragm pumps. Cavitation can cause significant damage to the AODD pump, which in turn can

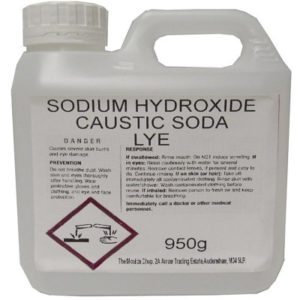

How to pump Sodium Hydroxide

Sodium hydroxide NaOH (common names – caustic soda, soda lye, white caustic, sodium hydrate) is one of the most commonly used industrial chemicals. It is

How to pump Sodium Hypochlorite

Industrial users of sodium hypochlorite (NaOCl), especially its highly concentrated solutions must utilize pumps that: Will prevent any spills of this extremely corrosive and harmful

Difference between passivation and electropolishing

Passivation is a chemical process of treating stainless steel in order to prevent rust by reducing chemical reactivity of its surface. Typically, nitric or citric

Solidification of the liquids

Solidification of the liquid which remain inside the pump for the certain period of time causes damage to the connecting rod, diaphragms holding plates, valves.

Dry Running of the Diaphragm Pump

Dry running is a one of the key features that differentiate Air Operated Diaphragm pumps from other types of pumps. In majority of the cases

How to pump Sulfuric Acid

The selection of the pump for sulfuric acid (H2SO4) must always take into consideration the acid concentration with its specific gravity, temperature, and the working

Pneumatic Pumps Freezing

Pneumatic Pump freezing is a result of thermodynamic adiabatic process in which change occurring within a system as a result of transfer of energy to

Feed Pumps for Filter Press

Air Operated Double Diaphragm Pumps are commonly used as a feeding pumps in filter press applications due to: Their versatility. Diaphragm pumps can handle different

What Diaphragm Pump for Ceramics

Ceramics industry require durable, abrasion resistant Diaphragm Pumps capable to transfer ceramic slip, sludge and glaze. Diaphragm Pumps for ceramics must withstands wear caused by

Multiport 1 inch Stainless Steel Pump

Unique 1″ pump model that has different type of fluid connections. This gives flexibility to use this pump as a mobile device that can be

blog about air operated double diaphragm pumps