Written by Rick

Solidification of the liquids

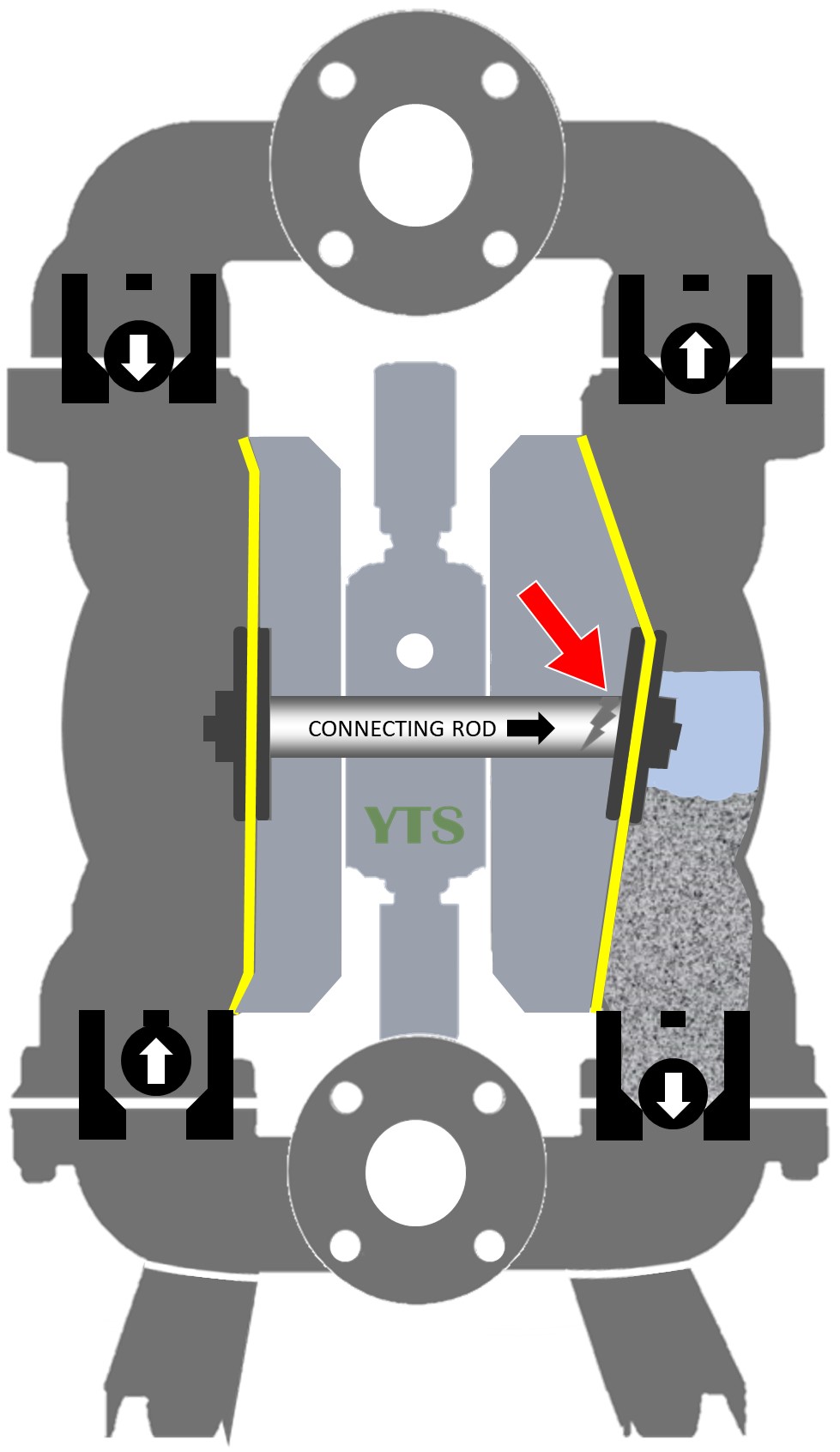

Solidification of the liquid which remain inside the pump for the certain period of time causes damage to the connecting rod, diaphragms holding plates, valves.

Fluids prone to solidification (such as ceramic pulps, glue, resins, tars, bitumen, sludge, etc.), which harden when exposed to oxygen in the air, solvent evaporation, water evaporation and temperature shouldn’t remain inside the pump and the piping if the pump won’t be use during some period of time.

The time during which products can be left unused inside the pump and piping system not endangering them is very different. It depends from liquid characteristic and pump working conditions. In generally, it is a period of few hours.

After pump work and prior hours of non-use a flushing should be made to avoid pump damage and costly refurbishment. When the pump flushing (which is the best option) is not possible, then valve on suction line should be closed, and the pump run dry from a few to a dozen seconds.

Another possible solution – is a usage of special YTS connecting rod made from hardened steel with a system of mounting diaphragms discs that prevent their distortion.

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which