Written by Rick

How to pump Sodium Hypochlorite

Industrial users of sodium hypochlorite (NaOCl), especially its highly concentrated solutions must utilize pumps that:

- Will prevent any spills of this extremely corrosive and harmful to human substance.

- Will minimize high propensity of sodium hypochlorite to off-gassing during pumping process.

PVDF, PTFE and Hastelloy are pumps body materials compatible with sodium hypochlorite.

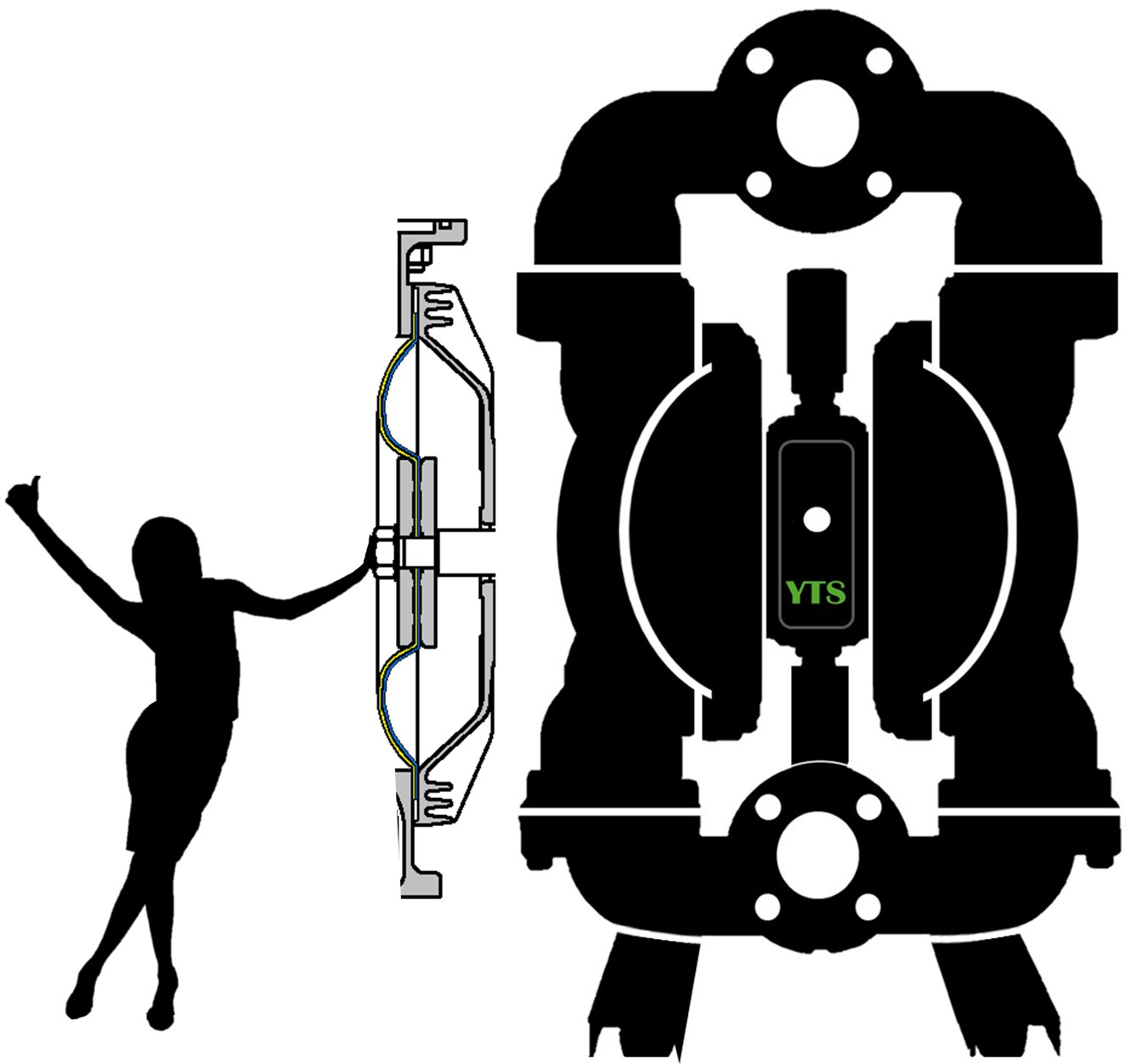

Diaphragm Pumps with short stroke length and high speeds should be selected, to lower the chance of gas creation and its accumulation inside the pump and piping system. Pumps should not be oversized. Higher size increases the amount of accumulated gas.

Applications of sodium hypochlorite are so diverse that the food and beverage industry, pulp and paper, paint and coatings, fish farming, agriculture, pharmaceutical, laundry factories, chemical industry, drinking water disinfection, wastewater disinfection stations, and healthcare can’t do without it.

We all encounter sodium hypochlorite in our daily life in every local store with household cleaning products. It is one of the best substances for fighting microbes, bacteria, viruses, molds and fungi.

Microorganisms die quickly even at the lowest concentrations of the sodium hypochlorite. Their outer shell and the surrounding biofilm are destroyed. There are myriads of consumer solutions of sodium hypochlorite which are manufactured and sold around the world.

Sodium hypochlorite oxidation reactions can be extremely corrosive. Its solutions when handled improperly can burn skin and cause severe eye damage. Sodium hypochlorite is poisonous if ingested, and chlorine gas is corrosive to respiratory organs.

Manufacturers of sodium hypochlorite and companies that use it for industrial purposes must be aware of the dangers that are associated with its production and handling. Majority of the pumps for sodium hypochlorite are used in industrial dosing applications.

Fundamental in handling of sodium hypochlorite is a reduction its propensity to off-gas creation during pumping or dosing.

Sodium hypochlorite solutions are prone to decomposition over the time. Time, concentration and temperature are the factors which determine decomposition. When sodium hypochlorite decomposition occurs, it transforms into a salt solution that generates oxygen bubbles. Oxygen bubbles accumulated in the suction line will affects priming characteristic of the pump.

The best pump for sodium hypochlorite is a high-speed pump with short stroke length. Only such a pump can reduce probability of gas accumulation inside the pump chambers. YTS Diaphragm Pumps with short stroke design are perfect for handling sodium hypochlorite.

Short stroke design significantly reduces probability of off-gassing during pumping of sodium hypochlorite.

YTS pumps with solenoid valve that can provide accurate metering are optimal choice for sodium hypochlorite dosing applications. They restrain harmful effects that off-gassing can have on the precision of the dosing process.

Dosing pump for sodium hypochlorite shouldn’t be mounted on top (above) of the storage tank. In such an installation, gas will enter suction line, pump and then discharge line. Exception – sodium hypochlorite concentration is very low.

The best, most effective installation is the one that has short, flooded suction pipe going down from the storage tank to the pump. With such a design of suction pipe gas bubbles will flow back to the storage tank, instead of running into the pump.

Pump and pipes should not be located in direct sunlight. The higher temperatures created by direct sunlight will increase the sodium hypochlorite off-gassing rate. Additionally, when heated above 35 °C sodium hypochlorite releases toxic chlorine gas.

Where possible, it is recommended to install purge valve on discharge line of metering pump, allowing any trapped gas to be evacuated.

Special attention should be paid to the pumps that do not operate continuously. In such a pumps gas can build up in suction line, pump’s chambers and discharge line. Installation with pump running intermittently should have bypass line with automatic valve that can recirculate sodium hypochlorite.

Sodium hypochlorite is versatile, widely used chemical compound in many kinds of manufacturing facilities in the world. It is corrosive and dangerous, especially its higher concentrations, when the pH exceeds that of eleven. It may pose danger to humans, environment, and be destructive to the facility if it is mishandled.

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which