Written by Rick

Difference between passivation and electropolishing

Passivation is a chemical process of treating stainless steel in order to prevent rust by reducing chemical reactivity of its surface. Typically, nitric or citric acid solutions are used to remove free iron from the surface of stainless steel.

The aim is to uncover chromium, that makes up at least 10% of the stainless steel. Chromium gives stainless steel its resistance to corrosion (also it hardens and toughens steel). Upon exposure to air, chromium binds with oxygen to form chemically inert oxide layer that protects steel from corrosion.

Passivation contrary to the electropolishing does not use electrical current to remove the top layer of material.

Electropolishing is an electrochemical process of in which outer skin of stainless steel is removed by anodic dissolution using electrical current passing through electrolytic solution.

The electropolishing process improve surface finishing by levelling micro-peaks and valleys, removing embedded contaminants, micro cracks and pits. Also removes heat tint, oxide scale and other surface imperfections.

Electropolishing leaves the stainless steel almost perfectly nonstick, as almost all of the microscopic flaws that debris would normally stick to are removed. Surface of the metal is visibly bright and shiny.

What type of pump to choose?

Passivation focuses solely on the formation of an oxide layer and will thus usually produce a thicker layer than will electropolishing. Chemically passivated metal surface has a double the corrosion resistance of an electropolished surface. Passivation does not smooth out the surface of the metal. It only protects it from corrosion.

Contrary to passivation, the main aim of electropolishing is to create metal surface with optimum cleanability, sterility, almost perfectly nonstick and with increased corrosion resistance (up to certain level). Electropolished pumps are commonly used in places where aseptic practices and procedures are involved. Applications in the food and beverage industry, pharmaceutical, cosmetics and semiconductor.

Often electropolishing and passivation are performed together to achieve metal surface with optimum cleanability and sterility, and the highest corrosion resistance.

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

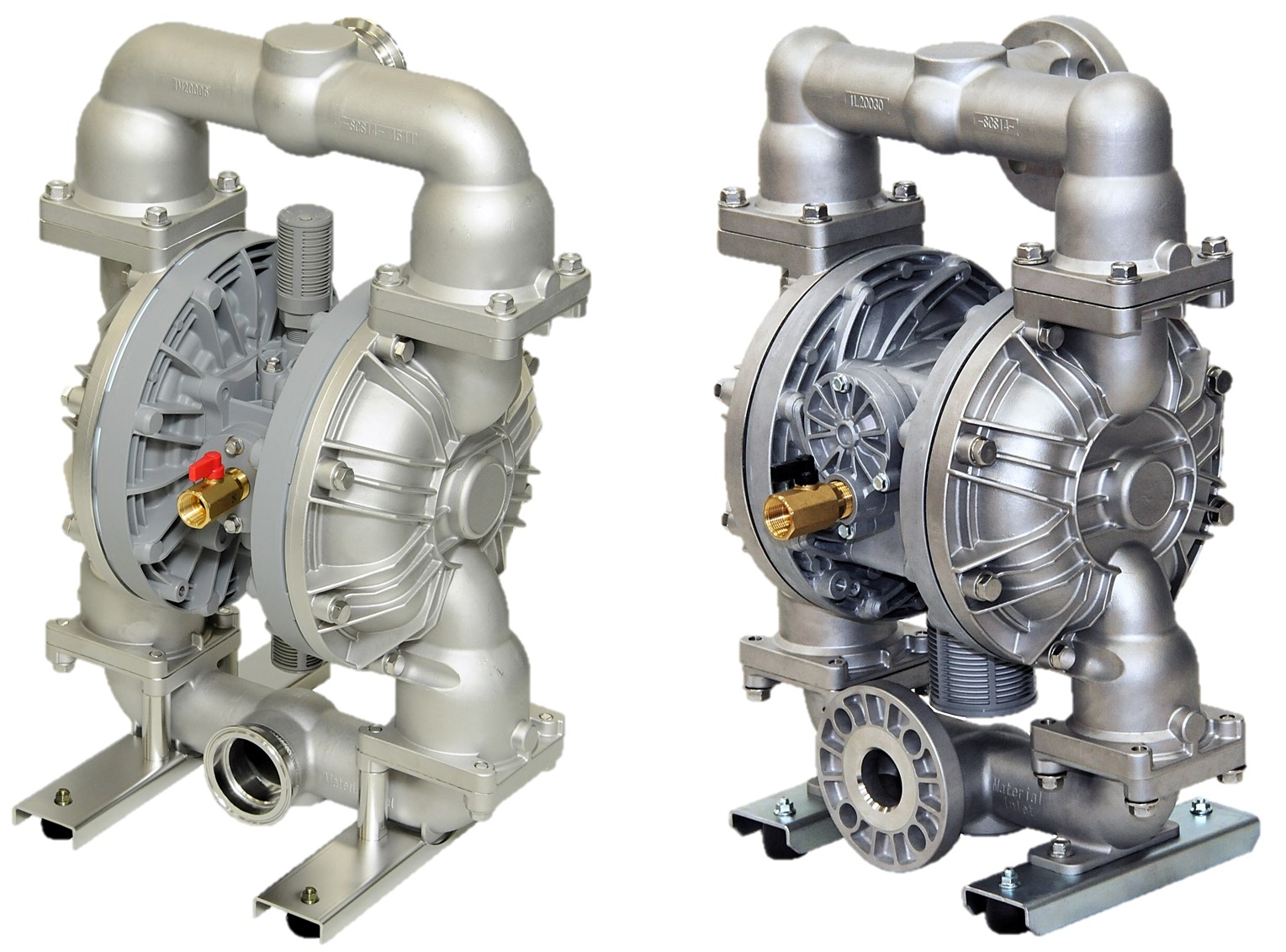

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which