Written by Rick

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments, under high-temperature and high-stress service.

YTS Air Operated Diaphragm Pumps manufactured from Hastelloy C-22 can survive in conditions in which pumps made from more common and less expensive iron-based alloys would quickly fail.

Hastelloy C-22 is used in applications, in which super austenitic stainless steels (AL-6XN®, 904L, and 254 SMO®) and duplex stainless steels (2205 and 2507) will not withstand extremely aggressive media.

It is a perfect material to be used in seawater applications and applications with salting fluids. Hastelloy alloy is almost unmatched when it comes to seawater resistance – this is especially true under crevice corrosion conditions. These conditions would induce attack in other commonly used materials such as 316 stainless steel, 6MO stainless and even Monel alloy.

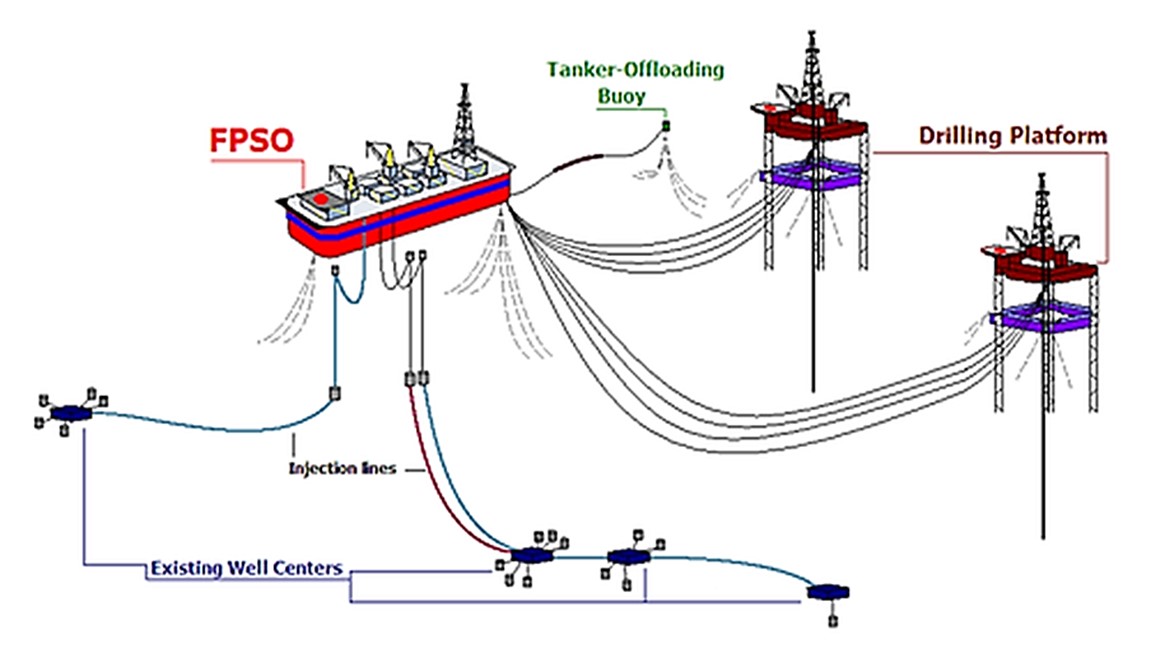

I would like to pay special attention to use of Hastelloy pumps in seawater applications. For offshore gas and oil platforms, offloading units – FPSO (floating vessel used by the offshore oil and gas industry for the production processing, and for the storage of oil), offloading vessel – FSO (vessel used only to store oil).

And, in fast growing industry in recent years – desalination of seawater.

Currently (2020), there are almost 21.000 desalination plants located worldwide. Vast majority (60%) of desalination plants operates in Middle East and West Asia.

Salt composition in seawaters varies from 10.000 mg/L of chlorides to 19.000 mg/L of chlorides for open ocean water (chloride, in the form of the Cl– ion, is one of the major inorganic anions, or negative ions, in saltwater and fresh water. Public drinking water standards require chloride level not to exceed 250 mg/L – at this concentration water has detectable salty taste). Some waters in regions with high temperature can have chloride concentrations as high as 25.000 mg/L.

Chloride concentrations:

• Typical Seawater – 18.980 mg/L

• Eastern Mediterranean – 21.200 mg/L

• Arabian Gulf at Kuwait – 23.000 mg/L

• Red Sea at Jeddah – 22.219 mg/L

In desalination plants reverse osmosis installations removes fresh water from seawater leaving concentrated brine. In this process Chloride concentrations can reach 35,000 – 40,000 mg/L. Thus, concentration double, that of natural seawater. For every liter of freshwater output, desalination plants which operates using seawater and thermal desalination technologies produce on average 4,0 liter of brine. YTS Hastelloy pumps are designed to stands such high corrosion / erosion environments.

Hastelloy C-22 has exceptional resistance to a wide variety of chemicals, among which are:

• Strong oxidizers such as ferric and cupric chlorides

• Chlorine

• Formic acid

• Acetic acid, Acetic anhydride

• Nitric acid

• Oxidizing acids with chlorine ions

• Ferric and cupric chlorides

• Many others organic and inorganic chemical solutions

Hastelloy pumps are used in wide variety of chemical processes. Examples:

• Cellophane manufacturing

• Chlorine spargers, chlorination systems

• Circuit board etching equipment

• Flue gas washer system

• Galvanizing processes

• Gas scrubber systems

• Geothermal wells

• Incineration cleaner system

• Leaching

• Nuclear fuel reprocessing

• Pesticide production

• Phosphoric acid applications

• Pulp and paper bleach plants

• Sulfonation systems

• Waste water

YTS Hastelloy C-22 pumps can be also used in processes of manufacturing of biopharmaceuticals. Hastelloy C-22 is recognized by the ASME BPE standard, which identifies several specifications in Part MM (Metallic Materials) and by U. S. Food and Drug Administration (FDA).

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which