Written by Rick

Air Diaphragm Pump Start-up Pressure

As a rule of thumb, the start-up pressure of Air Operated Diaphragm Pumps should be set at 2,0 bar. Then, manually using air valve increases to the required maximum pressure. Or, automatically by utilizing installed on air supply line Slow Start Valve. Starting Air Diaphragm Pump at the full, or too high air pressure creates violent, sudden shock for all pump elements. This can result in dramatic reduction of diaphragms lifetime. Especially vulnerable are PTFE diaphragms.

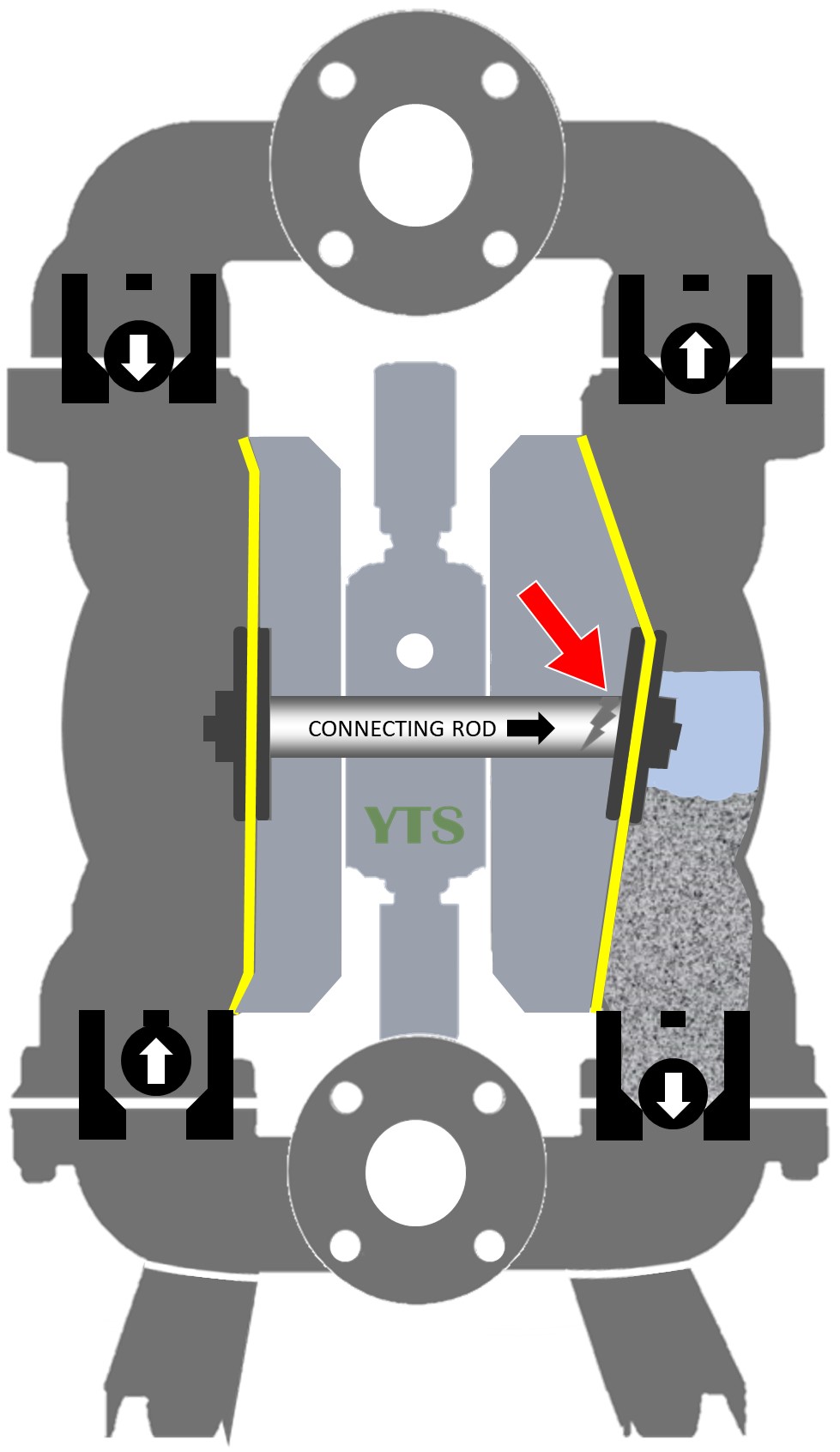

Too high supplied air pressure at the start-up, while the pump is not filled with a liquid cause diaphragm over stretch.

Valve balls have no enough time to close valve seat to create vacuum – pump capability to suck liquid into the pump is limited. Pump suction capability is reduced significantly.

When handling abrasive fluids, the settled-out solids should be expelled prior to the pump being operated at full flow and pressure. If this doesn’t happen, the settled solids can damage diaphragms, block ball valves. And in case of fluids prone to solidification bend or broke connecting rod.

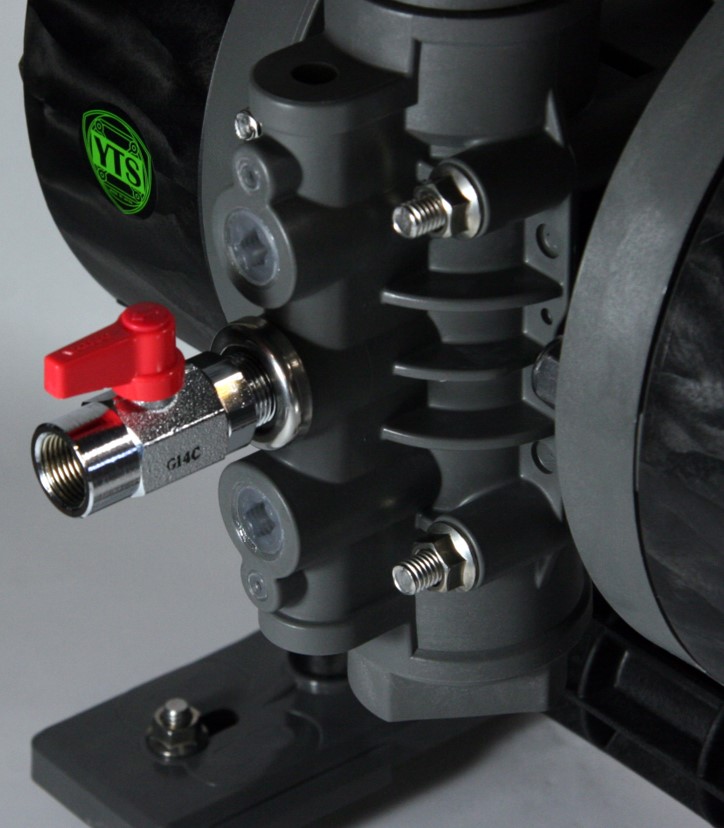

Slow Start Valve gently feeds compressed air into the pump, eliminating shock placed upon equipment. Reduces wear on the diaphragms and other parts, extending the life of the entire pump. Slow Start Valve with gradually increased air supply to the pump greatly improves suction lift ability of the pump.

The rule of thumb is to install Slow Start Valve with High Pressure Air Diaphragm Pumps.

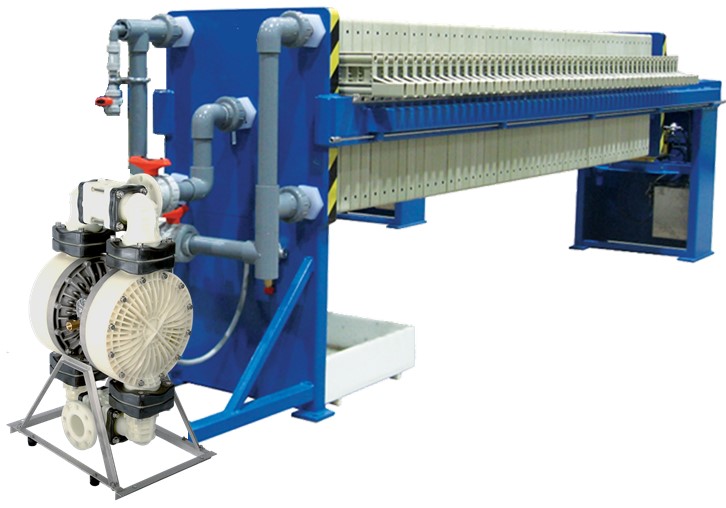

And with AODD pumps, which works as a feed pumps in filter press applications.

Unfortunately, this is often overlooked, causing premature diaphragm rupture due to unbalanced diaphragm pump operation in filter press applications. It is recommended to start filter press feeding process at 2,0 bar. Then, gradually increase the pressure at steady intervals to the maximum pressure. This protects diaphragms and allows gently transport of the solids to be filtered and filtration additives with the least possible shear stress.

We’ve got something exciting to tell you!

HELLO SWEDISH! We’re excited to announce that we’ve just launched Swedish language support on our website! This new addition to our language family has been

Indoor Air Quality

Indoor Air Quality (IAQ) – air quality within and around buildings and structures plays is of utmost importance not only for employees well-being and ability

10 Factors to Consider When Selecting Diaphragm

Diaphragms are one of the most important elements of Air Operated Double Diaphragm Pump. They separate the wetted side (fluid side) of the pump from

28 Reasons Why Use Air Diaphragm Pump

Air Diaphragm Pumps are so much versatile in design, materials, performances and functions, that they can handle most types of fluids. They are used for

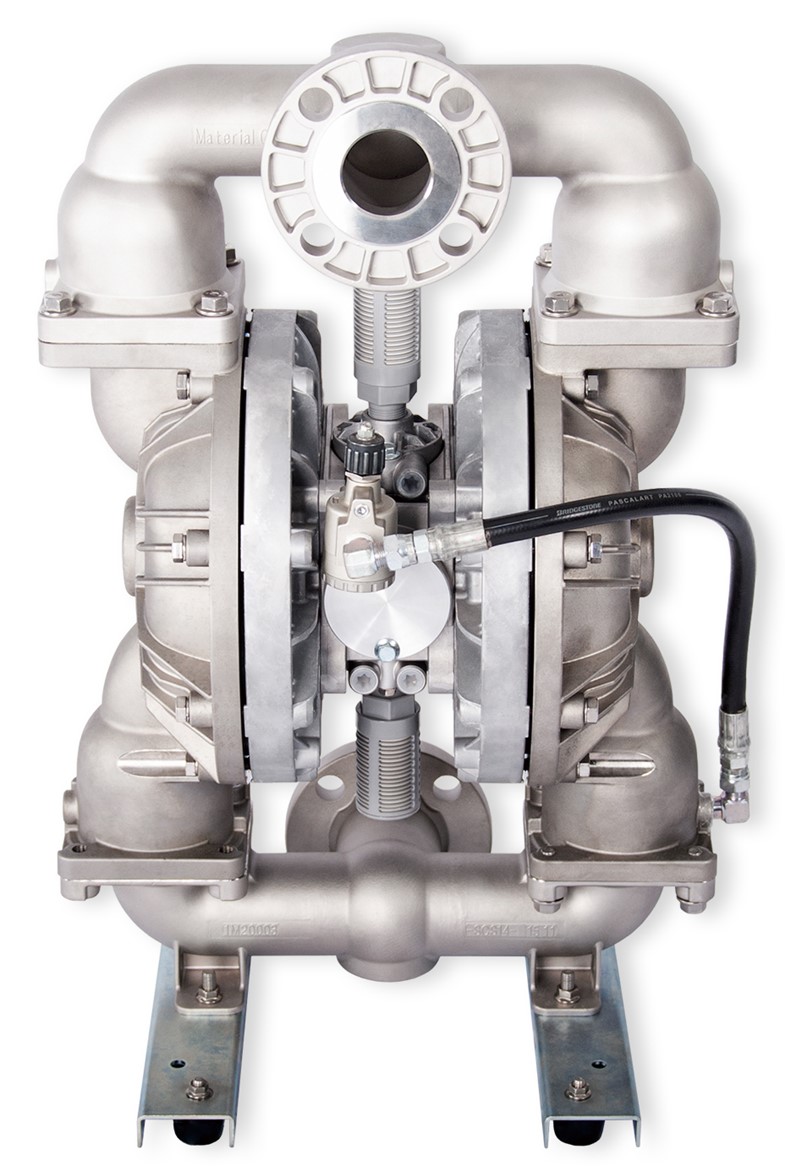

Hastelloy Air Diaphragm Pumps

The primary function of Hastelloy C-22 (also known as a “superalloy” or “high-performance alloy”) is a long-lasting survival in severely corrosive, or erosion prone environments,

Too Small Size of Air Supply Line to the Air Diaphragm Pump

It is not uncommon to use too small air supply line when installing an Air Operated Diaphragm pump. Overlooking restrictions installed along the line, which