Air Operated Double Diaphragm Pumps

2" Plastic

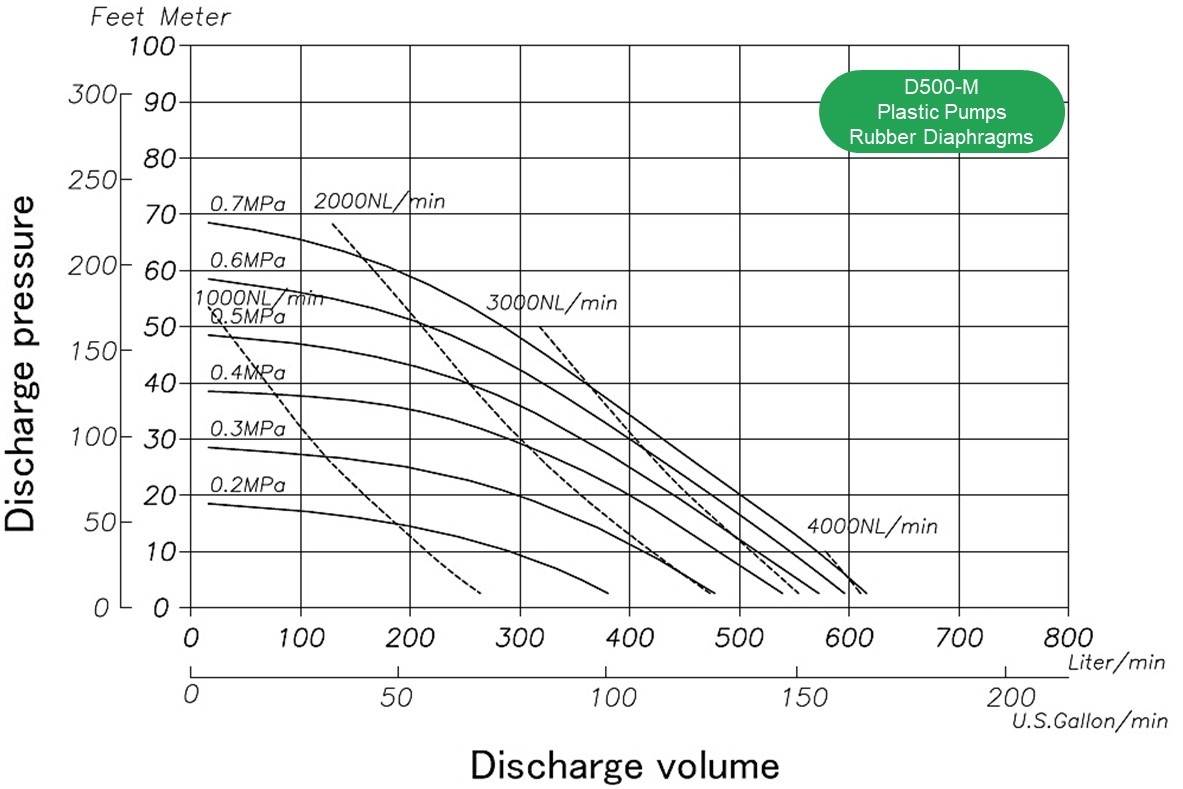

D500-M Heavy Duty

series

YTS powerful 2” Heavy Duty Diaphragm Pumps were specifically designed for very tough and demanding liquid transfer applications. Heavy Duty mechanically actuated shifting mechanism with non-centering coil spring assisted Air Spools will resist stalling and freezing in all conditions.

Heavy Duty Pumps are able to achieve high flow rates and high discharge heads. They are very reliable and efficient. Pumps possess high slurry and sludge handling ability.

They have fully bolted body, heavy weight construction and wide sturdy steel base. YTS Heavy Duty AODD Pumps are manufactured from high grade reinforced engineering plastics for mechanical strength, rigidity, abrasion resistance and chemical stability. They have double external exhaust ports.

Our pumps are oil and grease lubrication free, with zero exhaust air emissions for safe and environmentally friendly operation. They are easily maintainable with modular replaceable wear parts and outside accessible Air Spools.

Specification

Fluid Inlet / Outlet Connections |

2" FLANGED CONNECTIONS |

Maximum Flow |

620,0 l/min |

Air Motor |

ALUMINIUM |

Air Valve |

HEAVY DUTY MECHANICAL COIL SPRING AIR SPOOL |

Maximum Operating Pressure |

7,0 bar |

Maximum Size of Solids |

8,0 mm |

Pump Casing Materials |

GLASS FIBER REINFORCED POLYPROPYLENE (GFRPP), CONDUCTIVE FIBER POLYPROPYLENE (CFPP), CONDUCTIVE PVDF (Kynar) |

Diaphragm Materials |

PTFE, CR, EPDM, NBR, TPEE, TPO, FKM |

Options

• PTFE AND NICKEL COATED AIR MOTOR

• SOLENOID KIT DIRECTLY MOUNTED TO THE PUMP

• REMOTELY MOUNTED SOLENOID (ATEX)

Applications for Heavy Duty pumps

• PUMPING AGAINST VERY HIGH BACK PRESSURES

• OPERATING WITH VERY HIGH AIR INLET PRESSURES

• FREQUENT OR EXTENDED DEAD HEADING

• OPERATING AT VERY SLOW SWITCHING SPEEDS

• OPERATING WITH VERY LOW AIR INLET PRESSURES

• PUMPING CONTINUOUSLY FOR VERY LONG PERIODS

• FREQUENT START STOP APPLICATIONS

• OPERATING WITH VERY LONG DISCHARGE LINES

• WHERE PUMP ICING / FREEZING IS A COMMON OCCURRENCE

• WHERE AIR CONSUMPTION EFFICIENCY IS A CRITICAL FACTOR

Heavy Duty Mechanical Coil Spring Air Spool

• Mechanically actuated shifting mechanism

• Spring assisted non-centering Air Spools

• Resists stalling and freezing in all conditions

• Outside accessible

• Fully modular and replaceable wear components

• State of the art long life materials of construction

• Oil & grease lubrication free design

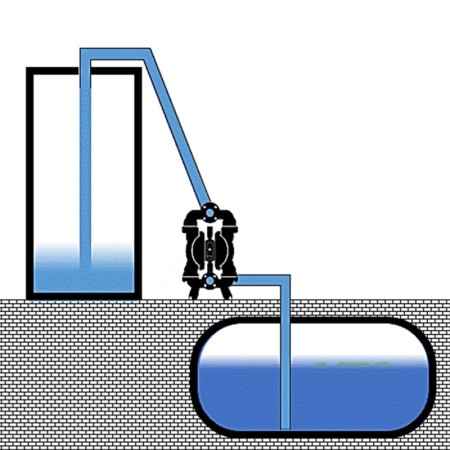

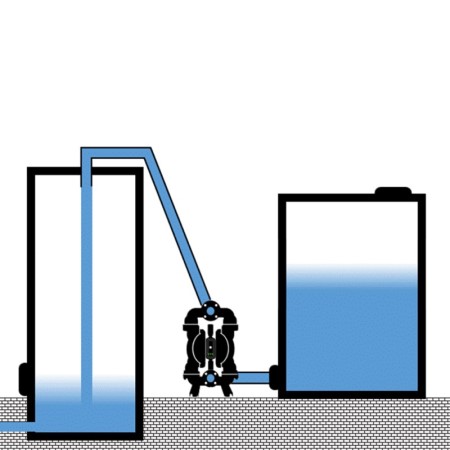

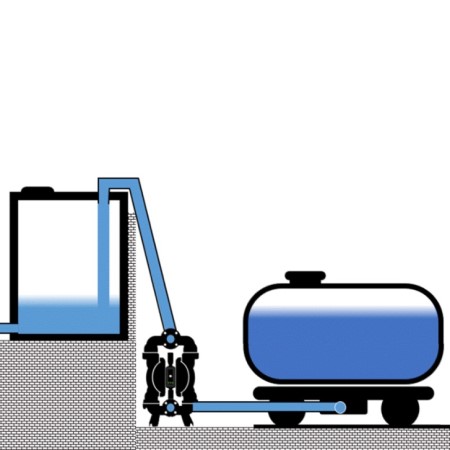

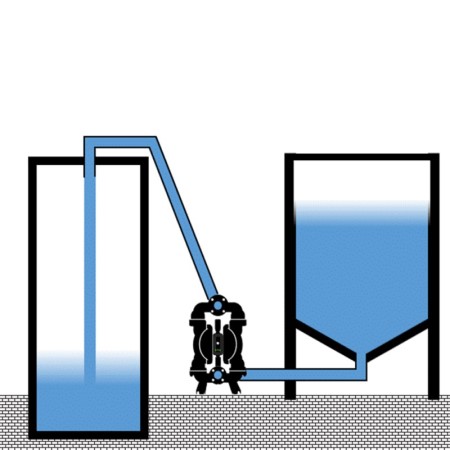

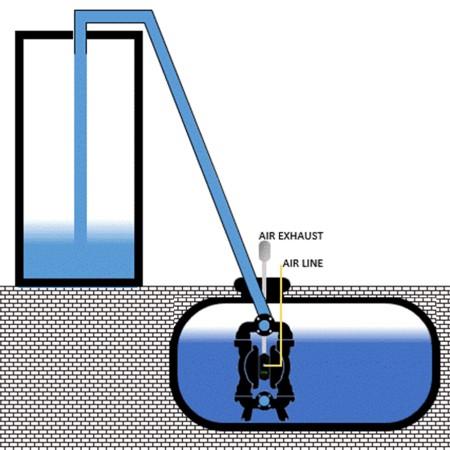

Air Diaphragm

Pump Installation

Related Items

ACCESSORIES

• Diaphragm Rupture Controller

• Filter Regulators

• High Performance Muffler

• Speed Control Muffler

• Liquid Inlet Filter

• TPO Backup Diaphragms

• TPEE Backup Diaphragms

• One up Diaphragms

Are you interested in this particular series of pumps?

Would you like to receive detailed information and price quotations?

Please Contact Us