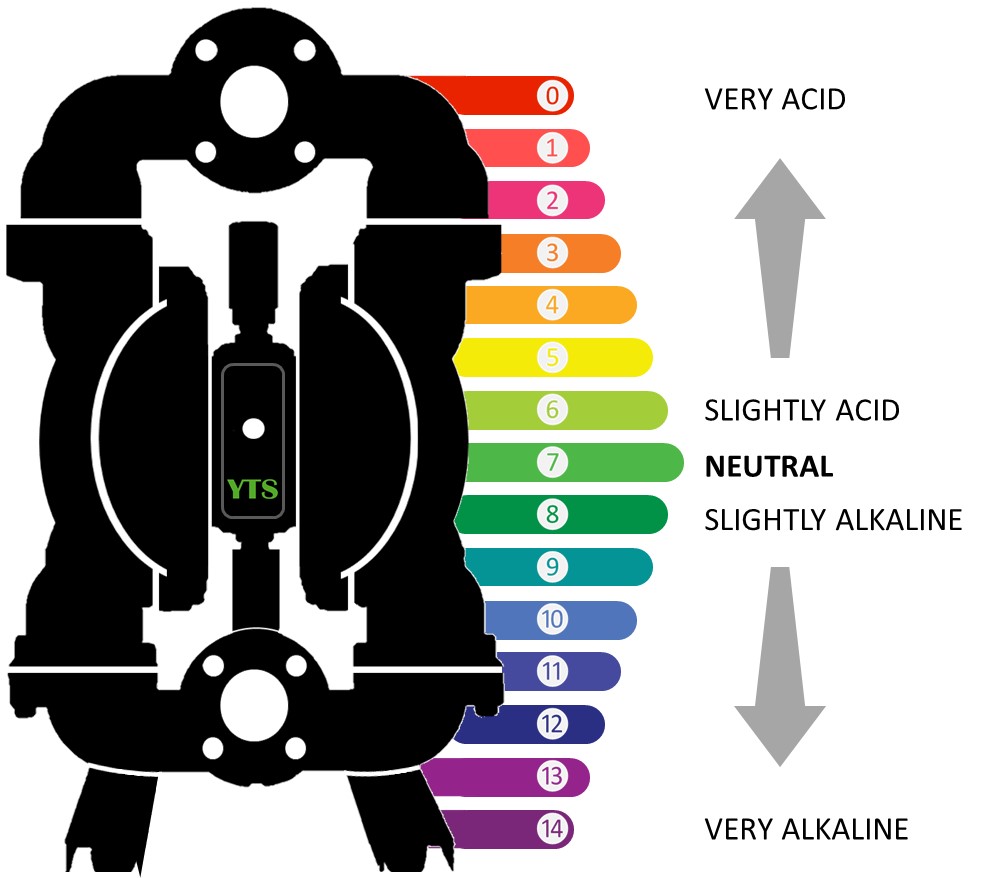

4. CAN HANDLE VAST VARIETY OF CHEMICALS

Diaphragm Pumps can transfer a huge range of chemicals including most types of acids, alkali’s, solvents, petrochemicals or even just water.

5. CAN PUMP VISCOUS FLUIDS

Diaphragm Pumps produce a relatively high discharge pressure and are able to move viscous fluids like oils, syrups, liquid resins, inks, glues, paints, pastes, etc.

6. CAN PUMP HIGHLY ABRASIVE LIQUIDS, PARTICLES AND LIQUID SLURRIES

There are no internal seals, rubbing or rotating surfaces so abrasive liquids with high solid percentage and large size of solids can be pumped easily. Diaphragm Pump can handle liquids that are not perfectly filtered – liquids with a residue of solid particles such as small stones, animal bones, crystals, sand or slurries. Large sized solids will pass just through the pump. Many types of liquid granulate can be pumped. Inks, paints, polish, caulking compounds, etc. can be pumped with ease.

8. PUMPING EFFICIENCY REMAINS CONSTANT

Diaphragm Pumps do not have any fitting parts, rotors, gears, or vanes exposed to the liquid and so do not wear out over time which normally leads to a gradual decline in pumping performance.

9. HIGH START-STOP EFFICIENCY

Compared to similar sized electrical type pumps, when used in constant start stop applications a Double Diaphragm Pumps actually offers a high level of pumping efficiency.

10. CAN NOT OVERHEAT

Diaphragm Pumps do not have electric motors and are cooled naturally during operation by the supply of compressed air, natural gas or Nitrogen.

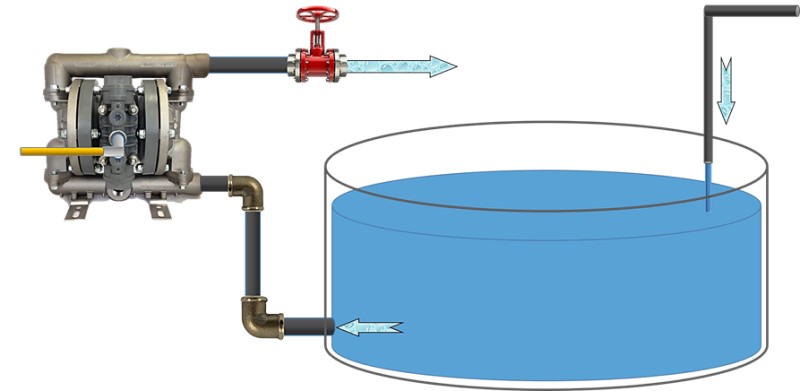

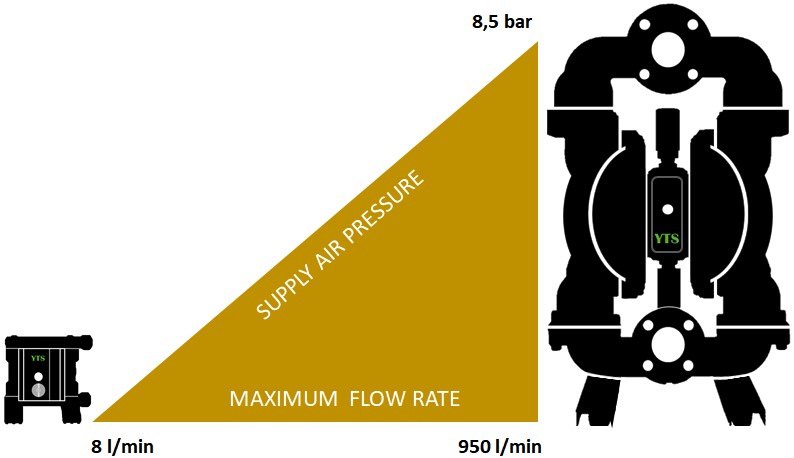

11. VARIABLE FLOW RATE AND DISCHARGE PRESSURE

By adjusting either the air inlet pressure or opening or closing the discharge valve it is possible to operate the pump anywhere between 0,1 liters per minute to full capacity. Discharge pressure is also changed according to air pressure (air pressure = fluid discharge pressure).

12. SHEAR SENSITIVITY

Due to the gentle nature of operation, Diaphragm Pumps are one of the best choices for shear sensitive fluids like wine, milk or ink. Also, they are a perfect choice for pumping reactive fluids such as detergents, shampoo or UV Ink.

13. HIGH-PRESSURE CAPABILITIES

Modified Diaphragm Pumps with a 2:1 pump air compress ratio are capable of producing close to 17 bar discharge pressure. 2:1 High Pressure Diaphragm Pumps are excellent for filter press applications.

16. SAFE, EXPLOSION PROOF

Air Operated Double Diaphragm Pumps use compressed air to operate and do not require any other electrical source and can be fully earthed. They can be used safely to pump all types flammable liquids or used in explosive environments (ATEX).

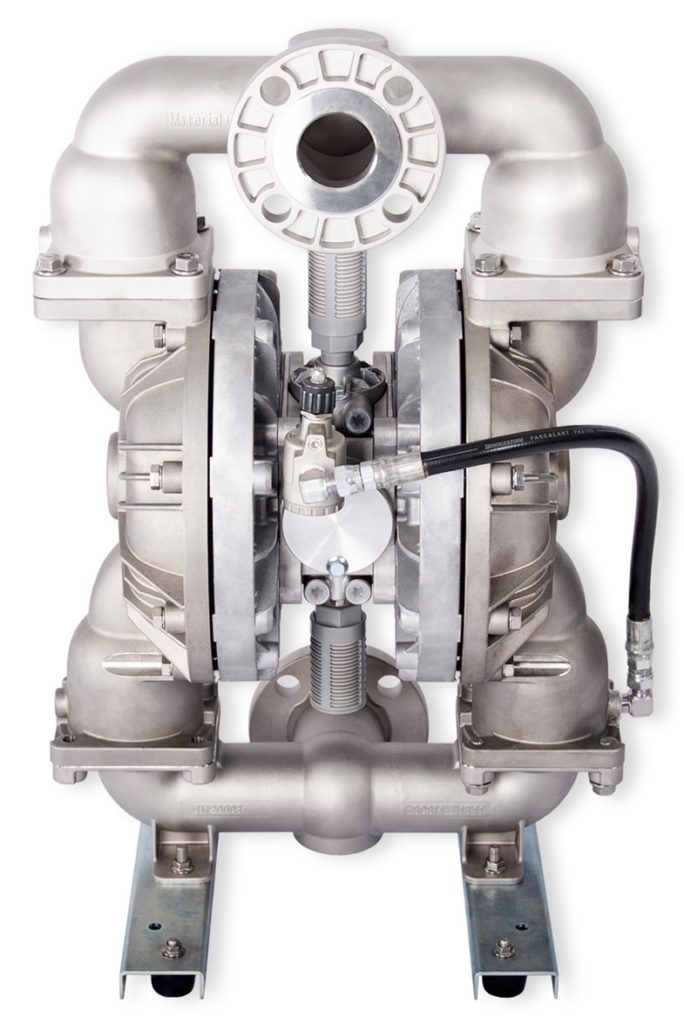

17. NO MECHANICAL SEALS, COUPLINGS, OR MOTORS

This eliminates the majority of leaks and costly maintenance associated with other kinds of pumps.

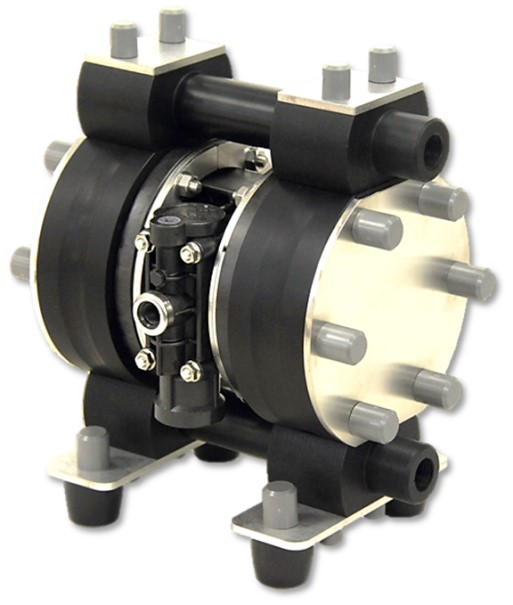

18. SIMPLE MAINTENANCE

In comparison to other types of pumps, the Diaphragm Pumps are easy to maintain. They have very few moving parts. They have no special seals or gears or electrical motor. They can be easily dismantled.

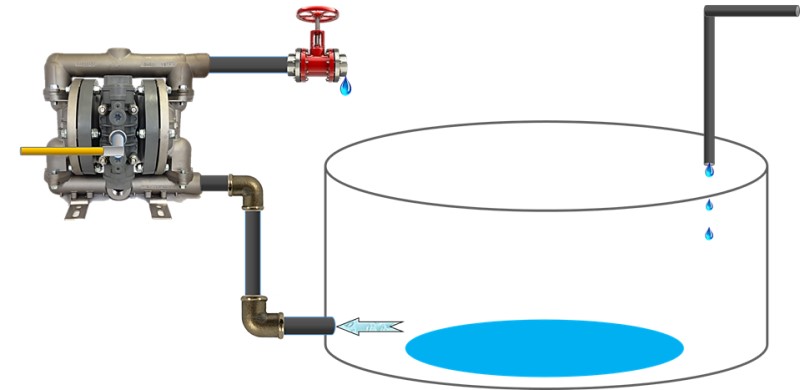

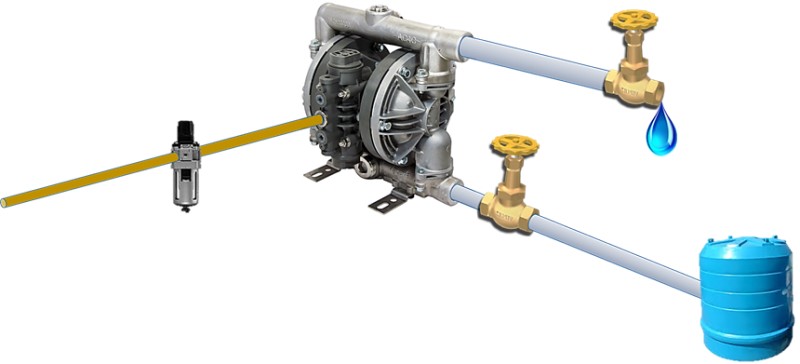

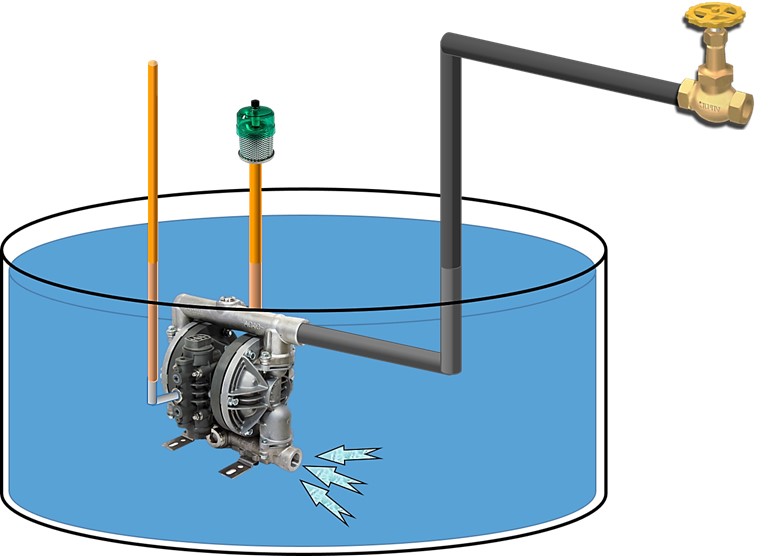

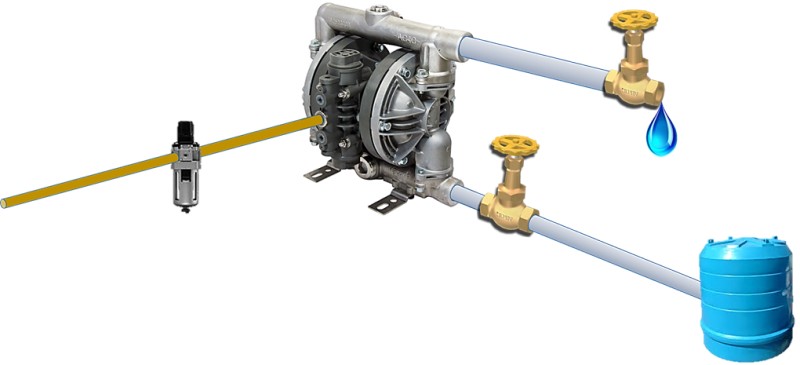

19. SIMPLE INSTALLATION AND OPERATION

By simply connecting air supply line and liquid lines Diaphragm Pump is ready to work. It is not necessary to mount or fix the pump in place. There are no complex controls, fittings or motors to install and operate. Start and stop the pump with either an Air Valve or air regulator or even a liquid valve.

21. INEXPENSIVE

Compared to other similar performance pumps, Air Operated Double Diaphragm Pumps are often cheaper to purchase and are easy and inexpensive to operate and maintain. Using a Diaphragm Pump can cut down on the “Cost of Owning a Pump”. This feature alone is a major reason to choose Diaphragm Pump over many another kind of pumps.